What does the cooperation look like?

The Business Stage

Submission and assessment of the inquiry. Followed by the processing of the inquiry and preparation of an offer. Once the offer is agreed the contract is being signed.

Preparation of a project

Technical consultation regarding the design of a specific part, concept of an injection mould and customer’s requirements on quality.

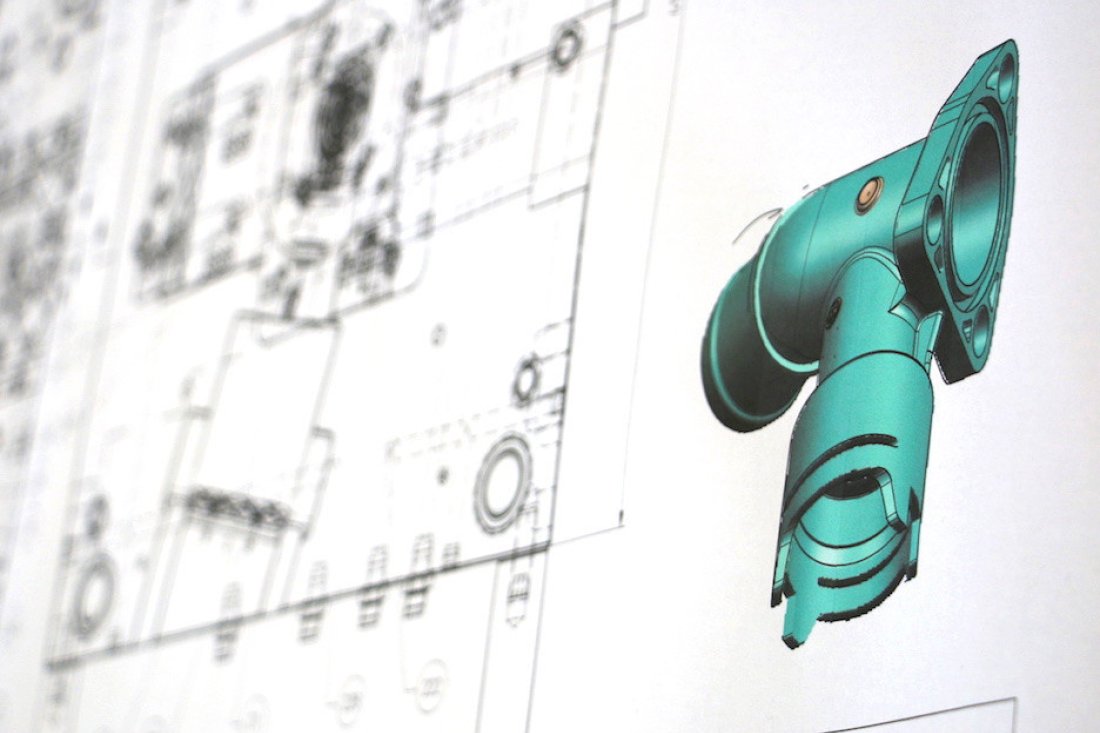

Development and design of the mould

Development and design of an injection mould in CAD/CAM system NX Siemens (including the mould flow analysis) takes approximately 3–4 weeks.

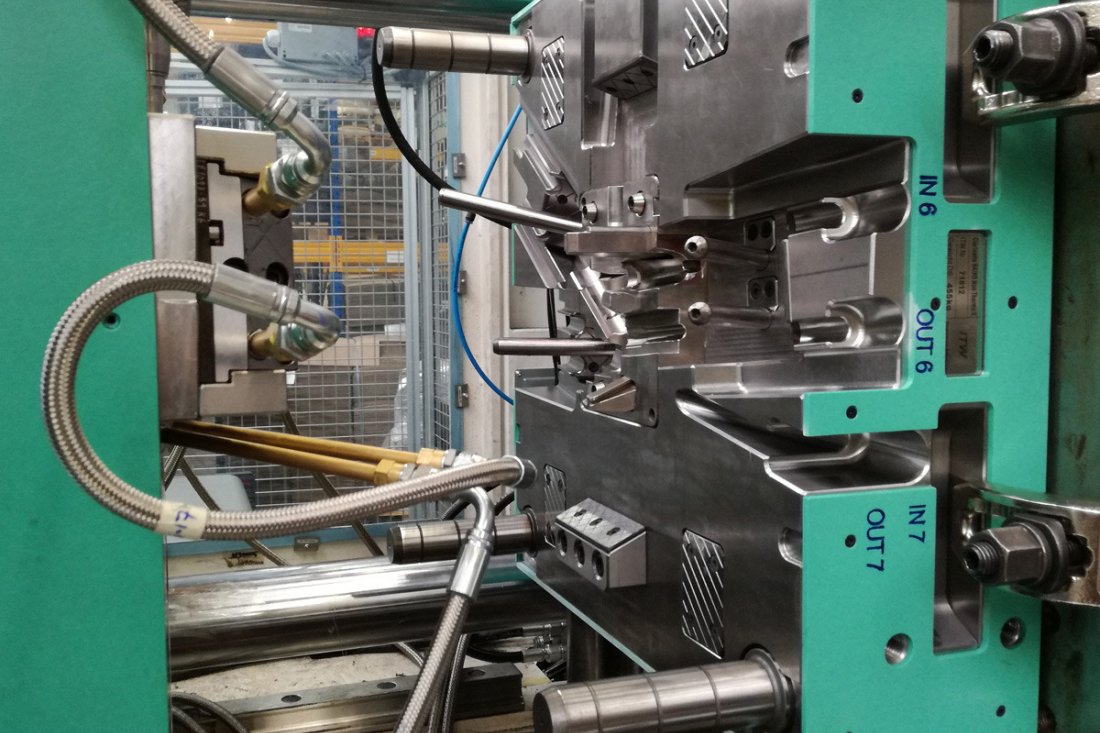

Production of the injection mould

Once the construction is signed off, the production of the injection mould begins in our own tool shop. The production takes 8–12 weeks depending on the complexity and the number of cavities.

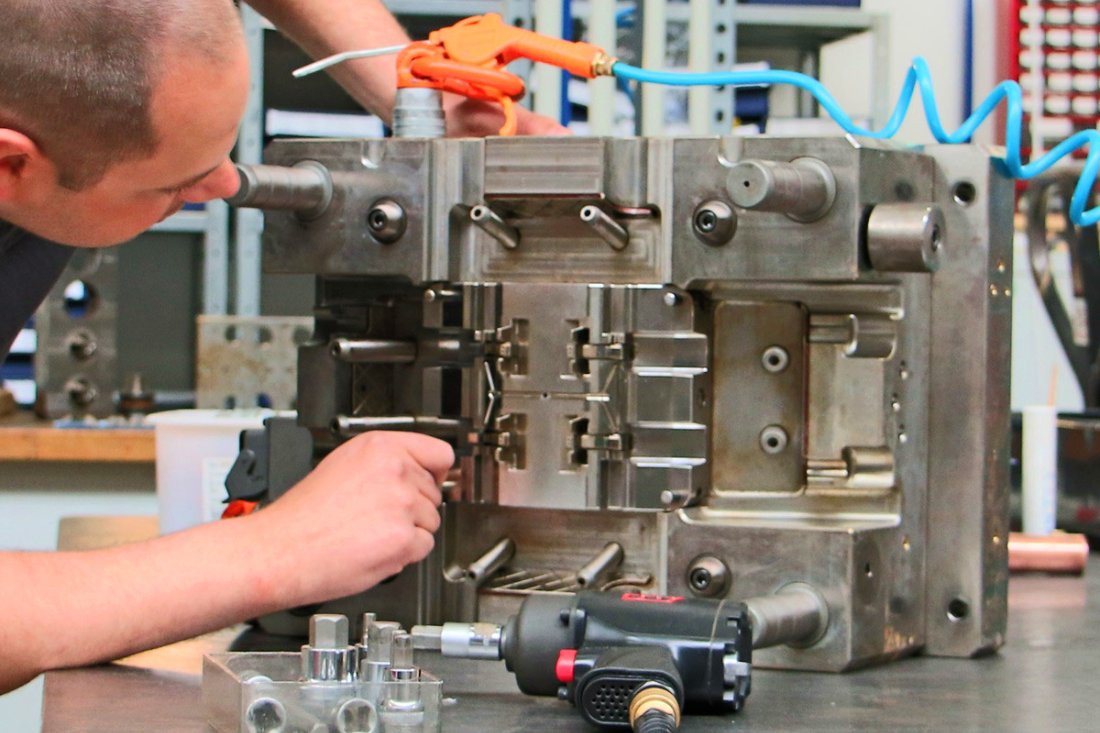

Testing of the mould

Testing the mould in own moulding department followed by an immediate dispatch of the first samples to the customer. The complete measurement report (ISIR) is sent additionally.

Mould (parts) approval

Possible corrections of injection mould and its final approval by the customer for serial production.

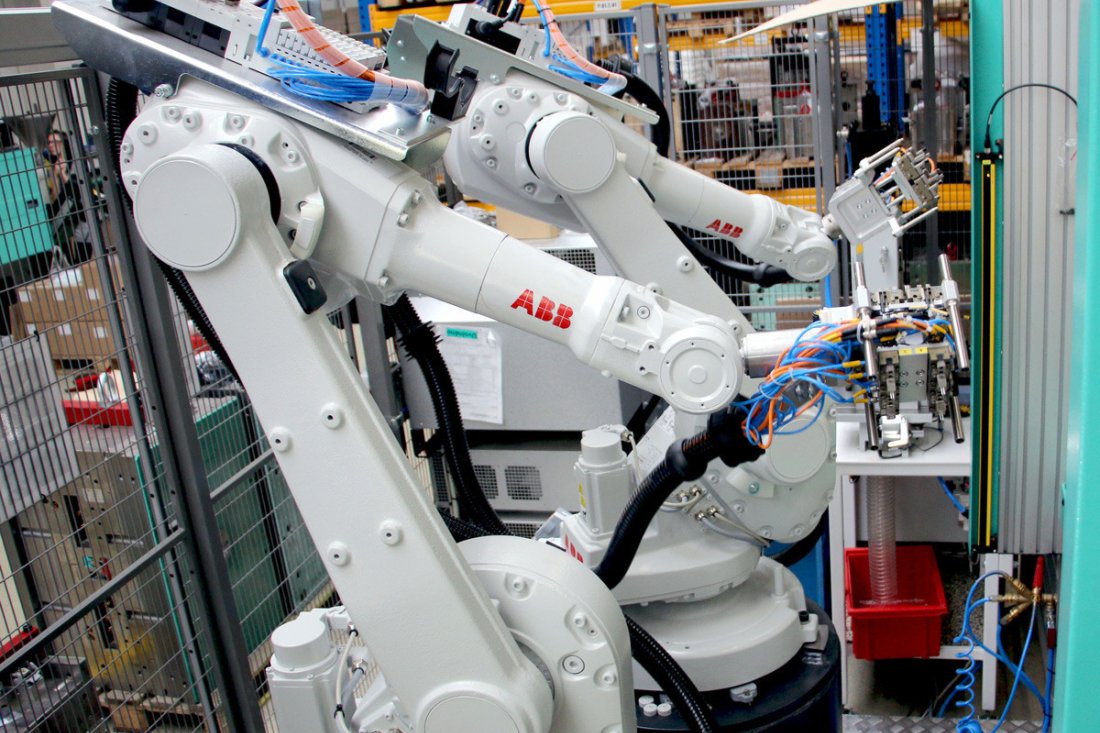

Serial production of the plastic parts

Mass-production of the injection moulded parts (including overmoulding with metal parts) according to the orders and forecast from the customer.

Assembly

In the case of customer demand, we can provide an assembly of several plastic and metal parts together. We use single purpose and ultrasonic welding machines.

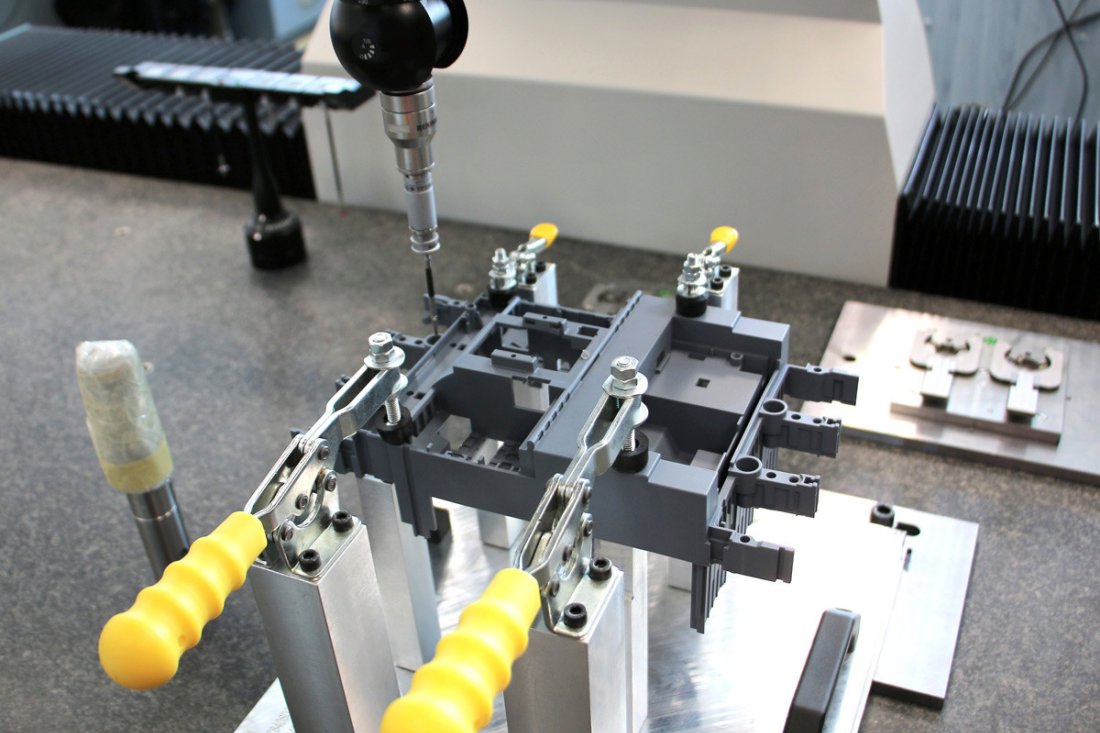

Inspection

Serially produced plastic parts are regularly visually checked and measured according to the customer´s specification.

Warehouse and dispatch

Serially produced plastic parts and assemblies are stored here and delivered by an internal or an external carrier.